Hi there!

Interested in solar dryers?

Want to know some basics and types of dryers?

You have come to the right place, let me walk you through………….

Did you know that Solar drying technology has a history of 70 years?

Solar drying technology was invented around 1950’s as a solution to the common issue related to open sun drying.

But much attention for the technology was gained later, after the oil crisis in 1973, when the interest raised in finding an alternative system with a sustainable energy source for grain and fish drying. Thereby Solar drying systems were developed.

However, solar drying became a popular subject from industrial to domestic scale drying applications specially in tropical countries like Asia and Sub Saharan Africa, where the solar drying potential is higher.

Solar energy used to dry rice in 1977, USA

A brief introduction on types of solar dryers.

More advanced solar drying systems are being developed through time and today based on the commodity nature, location, cost, and other factors that are of concern we can choose what is best for our purpose.

Let me give you a brief introduction to basic types of solar dryers.

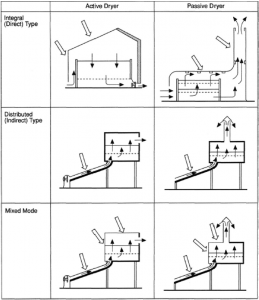

Conventionally, solar dryers are classified as follows,

Classification of Solar Dryers

Mainly it’s categorized based on whether it needs electricity or not. In active dryers, air flow inside the dryer is made by a fan powered with electricity while in Passive dryers it’s natural convection. Further, dryers are categorized into 3 main types namely Direct, Indirect, and Mixed-mode.

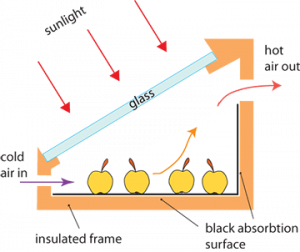

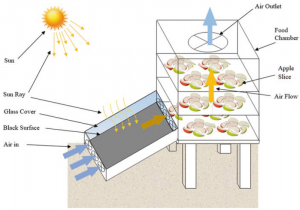

Direct Type Dryers

Direct type dryers are like a cabinet with a compartment with a glass roof. Here solar rays directly fall onto the commodity through the glass and with the greenhouse effect, it’s been heated. The airflow carries away the moisture as shown below. Tunnel, Greenhouse, and cabinet-type dryers fall into this category.

|

|

|

| Cabinet | Greenhouse | Triangular Roof Tunnel |

Schematic of Operation of Direct Dryer (top) and Examples (bottom)

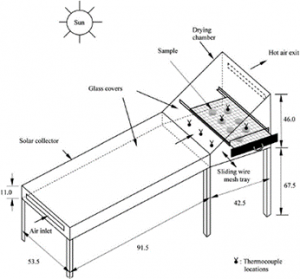

Indirect Type Dryers

Indirect type solar dryers have separate chambers for drying and heating airflow. In here there’s no direct contact between solar rays and commodity as shown in the figure below. Airflow entering from solar collector gets heated up and carries away the moisture from drying chamber.

|

|

Schematic of Operation of Indirect Dryer (left) and Example (right)

Mixed-mode Dryers

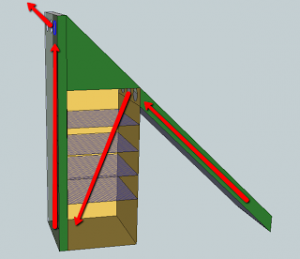

Mixed-mode dryers are a combination of above two types. The structure is similar to indirect dryer but drying chamber is made of transparent material so that the solar collector and drying chamber both get heated up by the greenhouse effect.

|

|

Schematic of Operation of Mixed-mode Dryer (left) and Example (right)

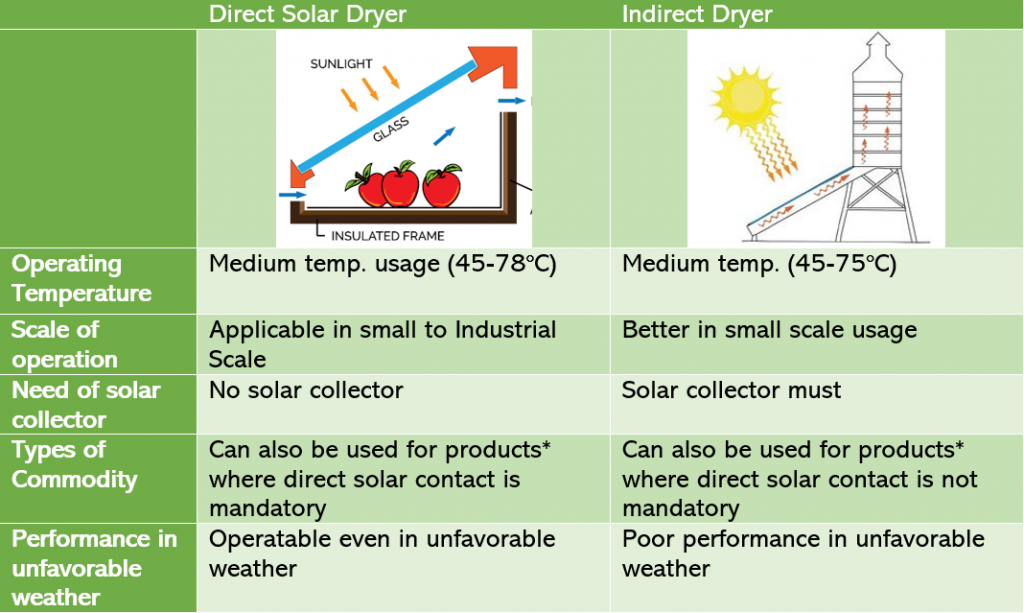

What is the Best?

Different types of dryers have their unique advantages. There’s no ‘best’ option for all applications. Taking into the nature of the commodity and other factors, best fit can be chosen. Therefore, it is better to know some facts and figures of different drying mechanisms, isn’t it? Let us give you some facts and figures of most common types of dryers.

General Information of Different Dryers

Products*- Crops, meat, fish, etc.

Overall, all these dryers can be made with locally available materials and still can achieve better quality products than open sun-dried products. But, understanding the nature of the product, applying proper materials, selecting appropriate mechanisms, and controlling the optimum conditions will make your dryer more productive and sustainable while making better profit margins.

That is why we are here for you, to share our expert knowledge, experiences, and cutting-edge technology in the field.

Is that all?

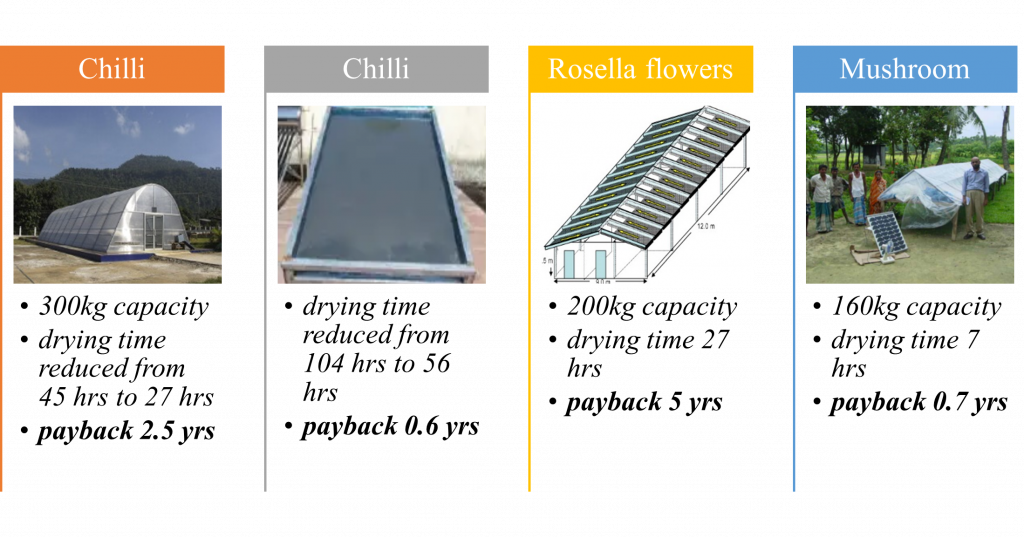

No. let us provide real-time examples where solar dryers were proven to be technically, economically successful, and sustainable.

Capacity, Reduced Drying time, and Payback Period of some Industrial Dryers.

What about Their Lifetime?

The lifetime of these dryers is more than 10 years.

However, lifetime of a dryer depends on the materials used in the construction. For example, in greenhouse dryers, the use of polythene or plastic materials is cheaper in construction, but lifetime is much lower, and productivity decreases with time. On the other hand, if insulated glasses are used instead, even though the initial cost is little higher, energy is saved, with extended lifetime.

Are you worried that Direct Sunlight would damage the Nutrients of your products?

Do not worry. We got an answer for that too!

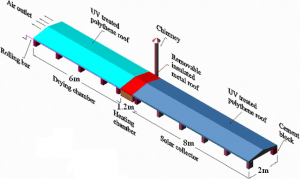

Downdraft Solar Dryer and Solar-infrared dryer are recently developed, innovative ideas to dry your product quicker without direct sunlight.

|

|

Downdraft Solar Dryer and It’s Schematic diagram

Solar-Infrared Dryer

Downdraft solar dryers can be operated in Active or Passive mode. It can provide a better solution for the space problem in large-scale drying as multilayer drying can be obtained as you can see in the above figure. These dryers can reach about 65 – 70oC maximum temperature.

Solar-infrared dryers have a very simple design but with very efficient drying. These dryers don’t need any electricity at all. And the operating temperature can even go up to about 75 – 80oC. It’s commonly used in single-layer drying and can be built at a very low cost with locally available materials.

In a nutshell

All solar dryers provide much better drying environment for products than open sun drying. Knowing the nature of the commodity, types of dryers, and sustainable use of materials help to gain better performance of the dryer.

Should you have any inquiries, we are here to assist you with a sustainable, cost-effective, and innovative solution.

I am interested in a greenhouse-type solar drying system. how do I go about this?

Hi Dwight, thank you for your interest in greenhouse solar dryer. You can contact our project engineer using this link: https://www.greenhousesolardryer.com/call/ .

I need a solution for drying mangos. I need something that will require NO electricity or fossil fuel. 100% solar. Ideally I would like to have an installation on each farm to eliminate the transport issues for whole mangos. There is a plentiful supply of local labour at each farm location. We will be processing only one type of mango that weigh 2-5 lbs each, so there would be lots of good quality mango pieces.

Hi Lawrence Levin, thank you for your interest. You can contact our project engineer using this link: https://www.greenhousesolardryer.com/call.