We introduced you the facts of different types of solar dryers. Today, solar dryers have improved in sophistication and efficiency as a result of technological developments and growing public awareness of renewable energy sources. Solar dryers are frequently employed as an alternative to conventional drying techniques that rely on fossil fuels in both developing and developed nations.

We would like to introduce a new solar dryer/drying technology presented by our partner, CONA Solar, which is the leading innovator of the solar drying technology in Europe.

Let's review the different types of solar dryers

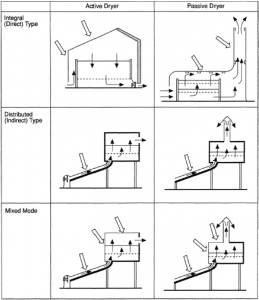

Active and Passive Dryers

Dryers are classified into active and passive types as shown in figure 1. Active dryers use an electric fan to create airflow, while passive dryers use natural convection.

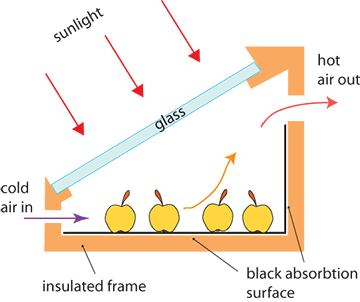

Direct type and Indirect type

Direct type of solar dryers are made up of a clear cover that allows sunlight to enter and warm the product, creating a natural convection flow that helps to dry it. The indirect passive solar dryer is a closed-loop solar dryer that uses solar energy in a contained chamber or cabinet to heat the air around the product to be dried. It is a different method than the direct solar dryer.

Introducing the new type of solar dryer - CONA Indirect Active Solar Dryer

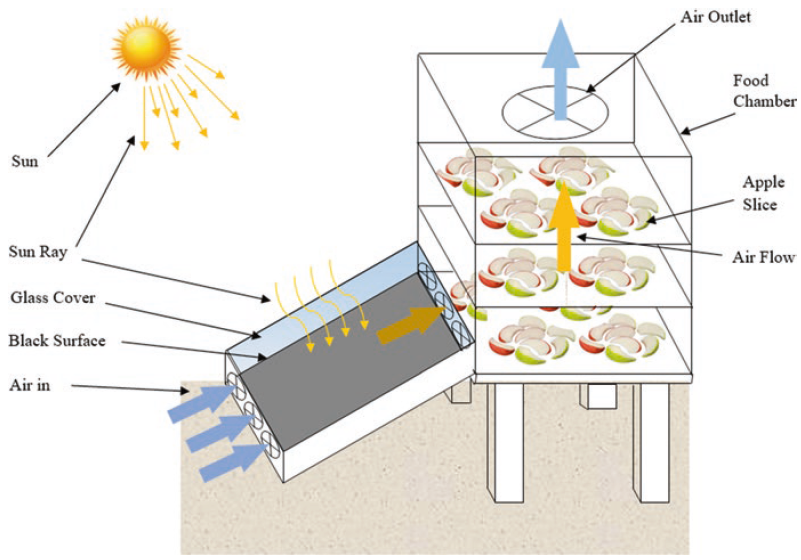

How does CONA Indirect Active Solar Dryer work?

The indirect active solar dryer is a form of solar dryer that uses a separate solar collector to heat a working fluid, then transmits the heat to the object to be dried using a heat exchanger. Because the product is not directly exposed to sunshine, this kind of solar dryer is indirect solar dryer. The thermal energy is transferred to the product using the heated working fluid, creating a constant and regulated drying environment.

The working fluid in an indirect active solar dryer is heated using flat-plate collectors or evacuated tube collectors. The product being dried is heated by the heated working fluid as it circulates through the heat exchanger. The hot air, which is often moved by fans or blowers, evaporates the moisture from the substance, leaving the dried product with its quality and moisture.

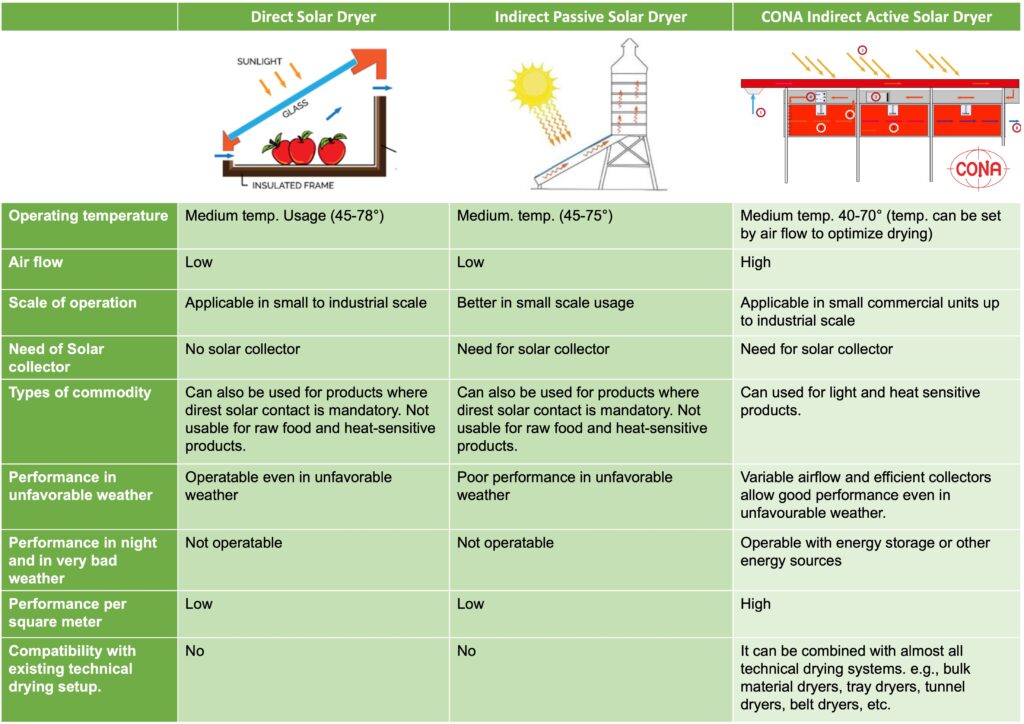

The table below shows the comparison between Direct solar dryer, Indirect Passive Solar Dryer and CONA Indirect Active Solar Dryer.

CONA's Solar air collector

CONA Solar is the leading innovator of the solar drying technology and is based in Austria. CONA was founded in 1987 and award winning invention, CONA solar air collector has dried more than 190 products in more than 50 countries.

CONA solar air collector produces warm, dry air that can be used for heating systems with air support and for drying. The invention increased the efficiency of warm air production for solar dryer and provide even drying performance in the chamber.

As shown in Table 1, the CONA indirect active solar dryer could provide a better efficient and consistent drying solution as the solar dryer is operated under a controlled drying environment with consistent performance. The CONA Solar air collector produces warm air more efficiently and directly. Besides, it is favourable to use for light and heat-sensitive products. Most importantly, it is flexible in energy sources and compatible with your existing technical drying setup. It is suitable for all small commercial units and industrial scale use.

In conclusion, the CONA indirect active solar dryer provides accurate control over drying conditions, effective drying, and is environmentally friendly. Yet, the choice of solar dryer to use depends on a number of variables, including the quantity and type of products, the area and resources that are available, any particular drying requirements, and cost and resource factors.

Should you have any inquiries, we are here to assist you with a sustainable, cost-effective, and innovative solution.